Nobody wants to have unhappy customers. Lean thinking guarantees that and this is how it can make it happen. ....

The most important of the lean activities that the lean company has to work very hard to pursue, is the value as perceived by the customer. Its products or services should match the customer needs, offering the best set of functions that maximise the customer’s satisfaction. Functions that are useless to the customer are a waste of cost and effort. They only add complexity to the product or confusion to the customer, worsening the value for money ratio. The question is, what is vital in organising an effective continuous innovation process?

The small and flexible cross-functional project team

Experience has shown that asking the customer is not always the best way to reveal the functions he is looking for. This information can be extracted by interviewing selected customers and even better by exposing them to product demos. These can involve for example tasting samples of products in case of foods, testing a fast built prototype in case of electronic appliances or software and interacting with a computer simulation model in case of housebuilding. This is best done by way of designing and executing small and smart experiments. A lean company has to have very efficient small product development and marketing professionals well integrated in cross - functional project teams. Each team should be built around each project by creating a cell. In the cell the cross-functional team members focus all their efforts to excel in time and quality looking at the customer “waiting” at the end of the process.

Time and quality are two interconnected targets and it must be clear right from the beginning that we cannot pursue one at the expense of the other. In other words we cannot buy time compromising on quality or vice versa, time and quality are not to be treated as trade-offs; time reduction and quality maximisation should go in parallel. It is crucial that each experiment is designed to test a few new important and properly prioritised functions. As a result of the execution of each small/smart experiment, the team acquires new knowledge, quickly and properly validated by carefully selected measurements and metrics. The interviews with selected customers is a powerful tool to evaluate the initial assumptions about the value of the selected set of functions. Eric Ries gives an excellent analysis of that in his book “The Lean Startup”.

Rapid experimentation through the execution of small experiments

The design of small/smart experiments is a heuristic method to avoid the compromise of the time or the quality and at the same time facilitate and expedite the knowledge accumulation that will lead to the final product launch. The so called rapid experimentation is a vital element of a flexible product development project, which starts with the assumptions to be investigated and proceeds with the selection of the functions to be tested, the data to be collected, the fast execution of multiple trials via the production of Minimum Viable Product (MVP) prototypes, the interviews with selected customers that have tried the MVPs and the evaluation of the lessons learned. Important in the rapid experimentation is to start with simplified assumptions, restricted small market segments and gradually expand them.

The proper selection of the functions that are expected to satisfy the customer’s perception about value, in case of more complex products, can greatly be facilitated by the Quality Function Deployment (QFD) tool. The QFD is an excellent tool to convert the customer expectations into product functions and eventually into product specifications, in a structured way that eliminates design reworks and backflows between various departments and eventually promotes the due diligence in value creation.

The project management

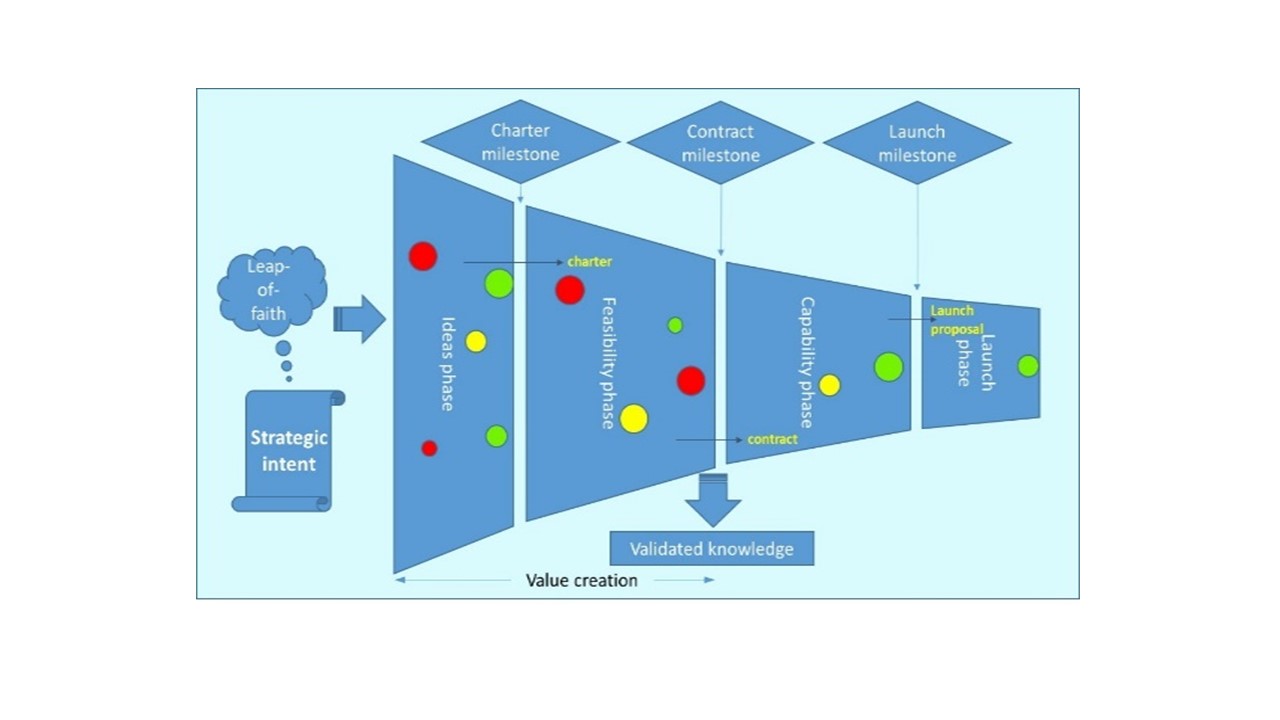

The collection of all the development projects in progress can nicely be managed using the product development funnel (PDF). This is, by the way, an excellent visual management tool. The PDF helps in  eliminating the accumulation of incomplete development work. Moreover it facilitates the proper allocation of the resources between the development projects, a job similar to the (lean) line balancing.

eliminating the accumulation of incomplete development work. Moreover it facilitates the proper allocation of the resources between the development projects, a job similar to the (lean) line balancing.

Each project passes through the ideas phase, with the set of assumptions to be tested, the feasibility phase, where the prototype is built and tested and the knowledge is extracted and validated, the capability phase, where the final product prototype is transferred to manufacturing and the launch phase. The feasibility phase could allow for some “reworking of experimental work” to ensure the optimum selection of the proper set of functions leading to fulfilment of the customer’s perception of value. This may be required, on top and despite the use of the QFD tool, to verify that the project team has really captured in the prototype the most vital customer requirements. But how can we reduce the project lead time?

The flow achieved through the milestones

The milestones illustrated in the PDF figure above are the points, where each project is tested whether it fulfils the criteria to proceed to the next phase. The milestones ensure the development projects are on track both in content (quality) and in time. The colour code signifies the readiness to proceed to the next phase. The relative position on each phase indicates the percentage of the time spent, compared to the total time allocated to the project for the phase. The size of the circle represents the amount of resources allocated to the project in this phase.

Proper milestones management is indispensable to keep the project on track towards its target and to shorten the project lead time. No projects should be allowed to accumulate in any phase. A red project located in the end of a phase means that it has consumed its time allocated for this phase but does not fulfil the requirements yet, to proceed to the next phase. It is up to the product development leader to use his discretion to enforce the resources of the responsible project team or to discontinue the project. The proper management of the progress of the projects through the PDF phases ensures the implementation of the “flow” principle of lean management.

The pull ensured through leadership

Equally important is the selection of the projects in the idea phase. At this point the initial assumption on which the project is rooted, also known as leap-of-faith, is identified. This is a unique opportunity to establish a strong connection with the overarching company vision - its strategic intent. It also ensures that the right job is done in compliance with the business development priorities.

This implies that no project can start if it doesn't fit the business development priorities and no experiment can be designed if it doesn't satisfy the vital customers' value elements. As long as the vital customers’ value elements are in the core of the business development priorities, they are recognised as a growth opportunity by the company’s leadership team and they become a strong pulling force driving the product development process.

A successful continuous innovation

In conclusion, the lean concept in value creation is focusing in small/smart experiments, dedicated small project teams, knowledge accumulation, PDF/milestone management and leadership to enable:

- Elimination of the addition of useless functions in the new products or the new versions of the existing products, via the small/smart experiments.

- Elimination of the waste of effort and money caused by unsuccessful product launching, via the dedicated small cross-functional project teams.

- Achievement of flow in the product development job via implementing proper milestones management, which reduces the lead time or the product development time.

- Achievement of pull via connecting the value as perceived by the customer with the overarching business strategic intent.

The relentless effort put forward by the product development leader acting as the conductor of the development project teams’ orchestra and the implementation of the extremely efficient lean principles in connection with the small, flexible and focused cross-functional teams guarantee the best results in the continuous innovation.

It goes without saying that the implementation of a structured system has to be flexibly adapted to the reality of each individual company. During the implementation phase special attention should be given to the discipline required for the creation of flexible cross - functional project teams, the small and smart experiments implementation, the interviews with the customers and the milestones management. These activities are vital in organising an effective continuous innovation process.

The ingenuity and the discipline of the leadership team guaranties the successful implementation of continuous innovation. Flexibility and continuous experimentation to improve the innovation process is an excellent method for the business to achieve a unique value proposition.

29/8/2016

Alkis Charalambopoulos, www.leansolutions.gr

Key words: value creation, lean thinking, customer satisfaction, prototyping, small experiments, flexible cross-functional development teams, continuous innovation, value proposition, trade-offs, project development funnel, product development, rapid experimentation, Minimum Viable Product.