The Production Line Minitoring System (PLMS)

Why to monitor operational efficiency in the production environment? Well, there are a whole bunch of reasons why to monitor and measure the operational efficiency in the production environment of a consumer goods factory. The one and most important of all is that you don’t manage what you don’t measure.

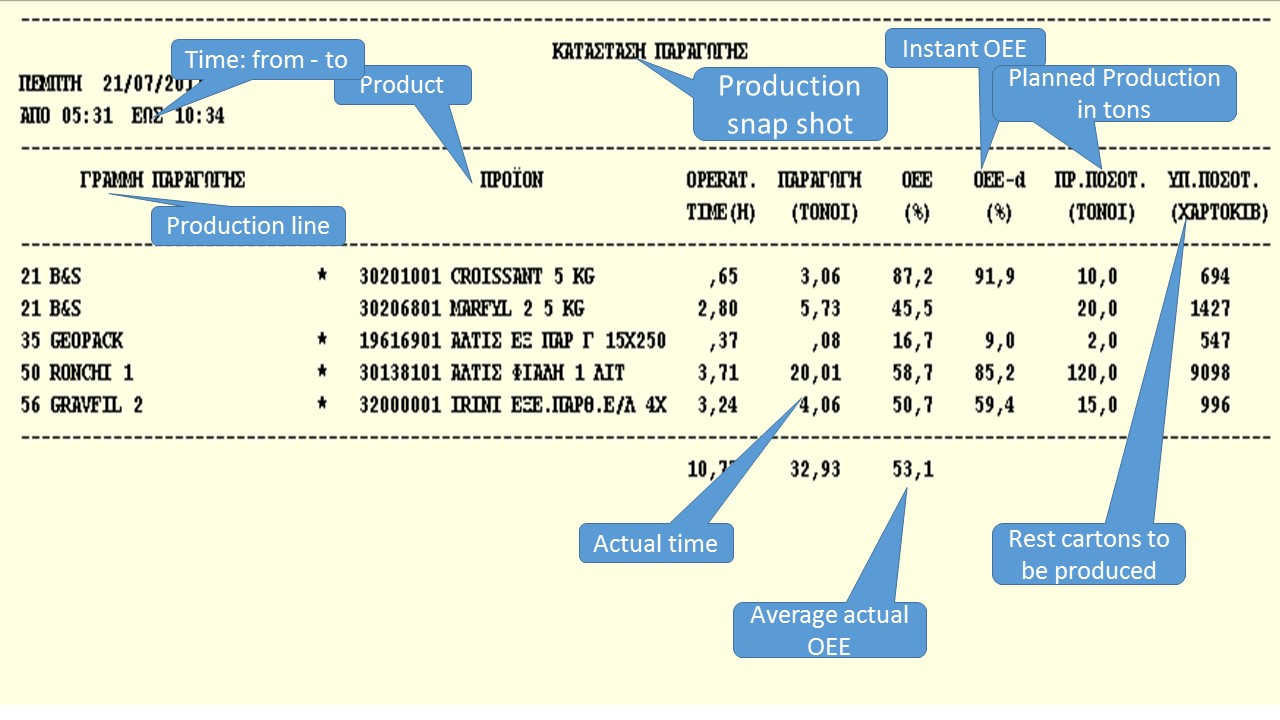

Let’s first clarify how the efficiency should be measured. To be effective the efficiency should be measured on – line, real – time. With PLMS this is effected by capturing at the monitor of each packing line all the downtime automatically the moment it happens. All that the packing line operator has to do, is to indicate the type of downtime by selecting the appropriate button on the touch sensitive screen of the monitor. The monitor collects at the same time the actual production and calculates the operational  efficiency of the packing line on – line, real – time. But there are a lot more built around the touch sensitive screen of the monitor of each packing line.

efficiency of the packing line on – line, real – time. But there are a lot more built around the touch sensitive screen of the monitor of each packing line.

The screen is the tool available to the operator to communicate with the ERP system of the company. It is on the touch sensitive screen that the operator receives through the ERP system the production orders that are to be produced on the specific packing line. The moment the operator selects the production order on his touch screen, all the label printing devices of his packing line are updated with the product code to be produced, the expiry date, if there exist any, and any other specific text to be printed. During the execution of the production order all the downtime and the quantity produced are collected by the monitor and sent to the factory server, which updates the ERP system of the company.

The operator is full in control of his production line because he can continuously monitor the actual operational efficiency of his line versus the target operational efficiency. He can then react to compensate for any efficiency loss or ask for help in case the deviation is big. The Production Manager is, through the server, fully aware of the production job any time during the day but also  of the statistics of the previous days. The PLMS helps therefore in quick problem solving activities. Besides, through the statistical data and the relevant visualisations, the operators with the support of engineering can propose improvement projects. They can also monitor the progress of the improvement projects observing the graphs. The engineering department can monitor the condition of the factory assets. The PLMS can feed the traceability system of the factory timely with accurate actual production data. Last but not least, it provides all the appropriate data to update the MRP.

of the statistics of the previous days. The PLMS helps therefore in quick problem solving activities. Besides, through the statistical data and the relevant visualisations, the operators with the support of engineering can propose improvement projects. They can also monitor the progress of the improvement projects observing the graphs. The engineering department can monitor the condition of the factory assets. The PLMS can feed the traceability system of the factory timely with accurate actual production data. Last but not least, it provides all the appropriate data to update the MRP.

In summary, the PLMS provides all the appropriate information for efficient problem solving (decision support), continuous improvement, production re-scheduling, visual management, asset management, traceability and MRP. Besides, the PLMS can further be expanded to effectively support the Maintenance function by integrating the maintenance work orders with the production work orders and become an esseintial platform of the factory. It is therefore the core of a management information system (MIS) and the cornerstone of the digital trnasformatin of the factory. Moreover it fits excellent with lean manufacturing in particular with “flow”, as it provides the metrics and the visual management requirements to enable operators and management to achieve uninterrupted flow of value to the customer. A last word of caution: in order to do all that and ensure a decent ROI, PLMS should be implemented wall to wall in the factory.

Contact us for any further information.

PROVIDENT an efficient production planning that prevents from building high stocks

Branded fast moving consumer goods (FMCG) industry is using make to stock production planning mode. This means that the production plan is based on the demand plan, which in turn is built from the sales forecast. The quality of the production plan depends on the accuracy of the inventory, the quality of the demand plan and the sales forecast. The latter should be timely updated and detailed enough to include any promotional activity; bear in mind of the “garbage in, garbage out” rule. The promotions are fixed in quantity and time and hence belong in the make to order mode. We conclude that the FMCG planning mode is a hybrid of make to stock and make to order. I would coin the term “make to plan”.

Being proactive in production planning requires very frequent updating, at least once per week. This is important not so much because of the changes in the demand plan but mostly because of the changes of the inventory. The production plan should cover twelve months ahead in rolling mode.

The production plan is front-loaded. This practically means that the first week is fixed, the next week is not expected to change a lot and the two following weeks can change to some extent. As we proceed to the next months the degree of certainty is diminishing. Keeping this discipline is very important for the suppliers planning, in particular for those that are located far away.

“PROVIDENT” is a very powerful planning algorithm. It has been successfully implemented in the packing operation of fast moving consumer goods companies. Its main optimisation advantage is that it builds stock, if any (e.g. in case of products with seasonality patterns), at the latest possible moment, based on the packing line capacities and the available time for production per week, “PROVIDENT” allocates the production plan in weekly buckets. Any shortage of personnel or any factory trial or investment project as well as any major planned maintenance activity in any period during the year is restricting the available time for production. To cope with the resulting capacity shortage, “PROVIDENT” moves automatically the non-covered demand to the previous week or weeks if necessary and builds the absolute minimum required stock. It goes without saying that “PROVIDENT” saves a lot of repetitive and complex planning routine and enables the error-free operation of a small but smart planning department.

“PROVIDENT” fits excellent in a multi-skill workforce factory. The multi-skill operators-maintenance technicians can easily move between production, maintenance jobs and improvement projects, nicely matching the fluctuating production plan with the maintenance and continuous improvement requirements. In other words, "PROVIDENT" enables the integration of production, maintenance and R&D activities.

Quick change-overs enable, through small production runs, the production of all the required products - or better SKUs (stock keeping units) - within the week and builds a fexible production schedule with the least possible finished goods stocks.

“PROVIDENT” requires a safety stock level to prevent any stock outs in the market. It also keeps very low stocks because it automatically adjusts the production plan to the actual inventory, which is immediately affected by any unpredictable sales variation.

Last but not least, “Provident” can easily integrate with an ERP software. It has been nicely inserted between the demand plan and the planning module of SAP.

In conclusion “Providence” is a flexible tool that integrates production with maintenance and improvement / investment projects and facilitates the implementation of TPM (Total Productive Maintenance). Besides “PROVIDENT” drastically reduces the inventory installing an effective pull system of the production from the demand, in line with the lean manufacturing principles.

Contact us in case of any further information required.